Project Summary

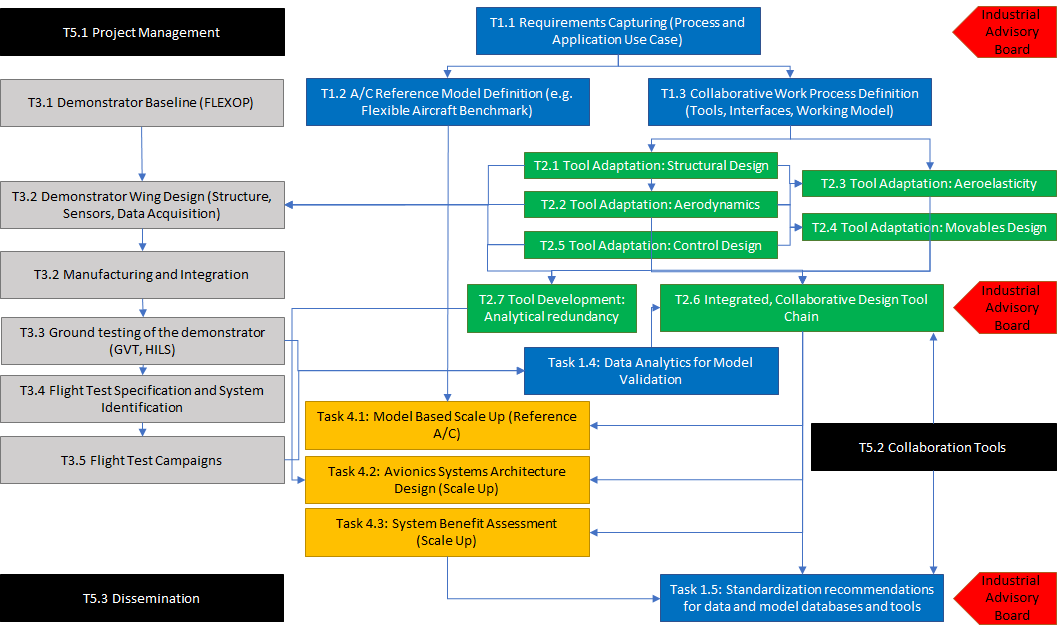

FliPASED is a 40 month long Research and Innovation Action, addressing the research aspects of multiobjective optimization of aircraft structures, control layout and gust response, by using all movable surfaces to shape the wing deformation to minimize fuel consumption in different parts of the flight, while using advanced sensor based feedback to mitigate gust response and improve comfort. The project is divided into 4 technical work packages and 1 management work package, as shown in Figure 7.

The project is organized in a logical flow, that research intensive work packages, WP1 (Toolchain definition for databases and tools), WP2 (Individual Tools and Methods) and WP4 (Scale-up), run parallel and precede the innovation intensive work package of WP3 (Demonstration), while later WP1 and WP3 feed back the achieved results to the tool chain development and validation in WP2 as well as through the open data approach to the academic and industrial context.

In the initial phase, requirements capture followed by model and process definition in WP1 feeds into application of tools in WP2, with providing consistent ways to obtain flexible aircraft models required for aeroservoelastic domains. Later in the project, designs developed in WP2 are realized in WP3, where ground and flight testing and experimentation are done. The obtained results will be used for prediction and by using the tools from WP2 these will be extrapolated in WP4 to assess the expected performance gains on a full scale aircraft.

The overall technology and methodology development will be fed back to industrial practice with connecting the results to standardization in WP1. The seamless multidisciplinary interaction will be inspired by project management in WP5 focusing beyond deliverables and milestones to coordinate teams and disciplines accordingly in a logical and timely manner, with special emphasis on establishing collaboration environment beyond the project itself.

Deliverables

| Number | Title | Description | Lead beneficiary | Download |

| D1.1 | Wing and demonstrator actuation and sensing conceptual design requirements | The deliverable will capture the requirements related to the attainement of proposed project goals. To be able to demonstrate wing shape control the shape of the wing has to be estimated and proper actuators with the adequate flight control surfaces have to be placed on the aircraft. The rationale behind the conceptual design requirements will be documented in D1.1. | TUM | link |

| D1.2 | Requirements capture for a/c MDO design | The requirements for Integrated, Collaborative Design Tool Chain are developed first within D1.2, since that lays the foundation of the experimental and analytical research within the project. The aircraft sizing cycle has to fulfil various constraints, while optimizing fuel consumption and passenger comfort, to name a few. So their tradeoff and the required fidelity in the preliminary design stage are described in the deliverable, including the proposed way to incorporate novel steps within the MDO cycle - including control system parameters. | TUM | link |

| D1.3 | Demonstrator ground and flight test requirements definition | To be able to demonstrate the proposed innovative a/c design cycle the flight test will have to provide sufficiently rich information for both iterative refinement of tools and methods and proof about their performance. According to the project objectives the ground and flight test requirements will be documented in D1.3 to be aligned with the remaining workpackages. | SZTAKI | link |

| D1.4 | Information and interfaces definition for Collaborative Work Process | The interdisciplinary teams within the project will share models, data and tools among them. D1.4 formalizes these steps within the iteration loops and establishes a document to define their interdependency and their standard interfaces (CAD, NASTRAN, Dymola, Matlab/Simulink, embedded C code). | SZTAKI | link |

| D1.5 | Reference Model Definition | Based on the expertise of partners a set of models with increasing fidelity will be set up, which provides a foundation for tools, interfaces and parameterization of models. The Flexible Aircraft Benchmark defined within D1.5 will also serve as a basis of the Scale-up (Task 4.1) where different candidate baseline configurations will be defined, and the Design Toolchain from Task 2.6 will be applied to these candidate configurations via the standardized interfaces. | DLR | link |

| D1.6 | Data Analytics for Model Validation | The data from flight tests will serve as a baseline to validate structural dynamics, aerodynamics, controls and avionics instrumentation models. Analysis tools with standard validation routines will be provided in Nastran and Matlab environment for structural dynamics and controls respectively. These tools along with Python based data science software will be used within the project and the underlying theory along with interfaces of these tools will be documented in D1.6. | SZTAKI | link |

| D1.7 | Standardization recommendations for data and model databases and tools | Based on the lessons learnt during the adaptation of tools in WP2 and their successful application to the demonstrator platform (WP3) and to the scale-up task (WP4) the recommendations for an iterative modelling framework will be established and formally defined in D1.7. Data from aircraft design scale-up simulation and flight test data will be assembled into a logical format, with recommendations how to standardize the corresponding output – analysis and design pairs, respecting their interdependency. | DLR | link |

| D2.1 | Report on flight control system layout | Report describing the flight control architecture and structure. This control structure will address the complete integrated avionic process including aircraft shape, sensors and actuator locations and detailed control design. The aim of the report is more to detail the structure and tuning variables rather than the methodology employed to adjust them. This latter will serve as baseline for developments of WP2 activities. | ONERA | link |

| D2.2 | Report on tool adaptation for collaborative design | The report will consider at first the construction of parametrized structural model using CAD and FEM methods. Then, as a second step, the generation of reduced and parametric dynamical models, tailored to the analysis and the control design will be done. The purpose is to define an approach to bridge the gap between accurate and complex to accurate and simple models. | TUM | link |

| D2.3 | Analytical redundancy methods | In order to achieve the project goals with a reliable avionics architecture the already installed sensor and actuator settings will be used in a novel to define input and output blending, as well as novel sensor and actuator fusion to provide fault tolerance. In addition, the challenging and open problem of optimal sensor/actuator selections is investigated in relation to the novel movables design. The document will describe the proposed FDIR and sensor-actuator selection methods and their application to the demonstrator aircraft configuration. | SZTAKI | link |

| D2.4 | Validation of the integrated design toolchain for collaborative design | Validation of the integrated design toolchain for collaborative design, based on re-engineering of FLEXOP -1 wing characteristics and design. | DLR | link |

| D2.5 | Aero-servo-structural design of the new advanced FliPASED wing | This report addresses the way to construct an Aero-servo-structural design of the new advanced FliPASED wing. | TUM | link |

| D2.6 | Validation of data science based methods for modelling and control | This report addresses the aspects of linear (parametrized) model approximation of dynamical systems, in view of control design. The model-free, or data-based approaches and their application to the flight data specific objectives will be described within the deliverable. In this work we are adopting big-data techniques to analyze the vast data provided by the complex sensing and control system. These methodologies are useful in mapping and revealing the underlying structure of the problem. Data science technologies for optimal usage of these data are developed in FliPASED, and recommendations for methods and useful sensor arrangements for future aerospace applications are described. | SZTAKI | link |

| D3.1 | Flight Test Programme - Flight Test Phase #1 | A detailed flight test programme is established defining the test objectives, means of compliance, requirements on specific test procedures to be followed. The Flight test programme also specifies abnormal behaviour measures and quality gates. | ONERA | link |

| D3.2 | Flight Test Report - Flight Test Phase #1 | Based on the Flight Test programme for the specific flight test campaign the test conditions, e.g. wheather, aircraft configuration, CoG, weight, will be documented as well as occurances or abnomalies during the conducted test flight. Flight test data will decribed with respect to formats, correction factors etc. | TUM | link |

| D3.3 | Flight Test Programme - Flight Test Phase #2 | A detailed flight test programme is established defining the test objectives, means of compliance, requirements on specific test procedures to be followed. The Flight test programme also specifies abnormal behaviour measures and quality gates. | DLR | link |

| D3.4 | Sensor concept advanced wing finalized | Based on the flight test programme and the formulated means of compliance a detailed sensor concept for the wings as well as for the overall demonstrator are established. This includes also the requirements and interface definitions on borad of the demonstrator as well as in the ground control station and the data link equipment. | SZTAKI | link |

| D3.5 | Manufacturing design for advanced wing | Based on the detailed design of the advanced wing from T2.6 all manufacturing related tooling design activities are performed. This includes design of molds, support structures, attachment structures as well as data model generation for machining and printing processes. | TUM | link |

| D3.6 | Flight Test Report - Flight Test Phase #2 | Based on the Flight Test programme for the specific flight test campaign the test conditions, e.g. wheather, aircraft configuration, CoG, weight, will be documented as well as occurances or abnomalies during the conducted test flight. Flight test data will decribed with respect to formats, correction factors etc. | TUM | link |

| D3.7 | Manufacturing advanced wing and fuselage finalized | The results of the manufacturing of the advanced wing are finalized. Special focus will be given to deviations through the production process versus the initial detail design of the advanced wing. The report will include all major characteristic data of the manufactured wing, e.g. mass, CoG. Due to the accident of the demonstrator several improvements are made to the overall avionics and structural layout of the aircraft. The corresponding rebuild steps are described in this deliverable as well. | TUM | link |

| D3.8 | Flight Test Programme - Flight Test Phase #3 | A detailed flight test programme is established defining the test objectives, means of compliance, requirements on specific test procedures to be followed. The Flight test programme also specifies abnormal behaviour measures and quality gates. | TUM | link |

| D3.9 | Advanced wing integration and ground test completed | Before closure of the wing structure all relevant systems, test equipment, wiring, sensors and actuators need to integrated and tested. A detail description of the final wing build-up and internal layout will be documented as well as results from the initial testing of the integrated equipment. Due to the fuselage rebuilt several additional tests are necessary to prove the flight worthiness of the aircraft what are also described in this deliverable. The DD actuator acceptance, taxi tests and the GVT for the improved demonstrator under construction are described in this deliverable. |

DLR | link |

| D3.10 | Flight Readiness Review Demonstrator with Advanced Wing | This deliverable presents a comprehensive analysis of the flight readiness of a demonstrator aircraft equipped with the -1 wing. The main objective of this report is to assess key factors that contribute to the flight readiness, ensuring the safe and successful operation of the aircraft. The evaluation encompasses various crucial aspects, including the airworthiness of the -1 wing, outcomes of the ground vibration test, system performance evaluation, flutter prediction, and the concept of operations (CONOPS) and emergency response plan (ERP). |

SZTAKI | link |

| D3.11 | Flight Test Report - Flight Test Phase #3 | Based on the Flight Test programme for the specific flight test campaign the test conditions, e.g. wheather, aircraft configuration, CoG, weight, will be documented as well as occurances or abnomalies during the conducted test flight. Flight test data will decribed with respect to formats, correction factors etc. | TUM | link |

| D3.12 | Flight Test Data published in Open Research Data format | The flight test data generated within the project will be published according to the standards of the Open Research Data Pilot. The deliverable is tightly coupled with the flight test reports and feeds into the public dissemination workshop at the end of the project. | SZTAKI | link |

| D4.1 | Scale-up design objectives | Captures and describes the design objectives for the scale-up study. | DLR | link |

| D4.2 | Scale-up aircraft re-design and control system lay-out | Control system lay-out to be used in the scale-up aircraft model. The parameters will be optimized within the MDO process. | ONERA | link |

| D4.3 | Report on quantified design benefits, as compared with reference | The report assesses the benefit gained with the developed design process on the scale-up aircraft model. | DLR | link |

| D5.2 | Project webpage and social media | The project website will provide information on basic project information, partners, publications, links and contact information. Mathematical models of the demonstrator developed for aircraft design will be posted on the project website, together with ground and flight test data of various aircraft configurations, to provide a benchmark for the entire community. Project news will be posted on Linkedin. | SZTAKI | link |

| D5.3 | Data management plan | The DMP will provide guidelines for the project partners with regard to all the datasets that will be generated within the project. The DMP will address the naming conventions, description of datasets, standards and metadata, and data sharing properties on a dataset by dataset basis. The DMP will be updated reflecting the current status of view on the data that will be produced, evolving during the lifespan of the project. | SZTAKI | link |

| D5.4 | 12 month Progress Report | The project coordinator submits an annual progress report to the European Commission, when it does not coincide with the EC mandatory periodic reporting, indicating the status of the project. The structure of this progress report will be the same as that of the periodic report. | SZTAKI | link |

| D5.5 | Exploitation and Dissemination Plan | Exploitation goals of the consortium and the planning of the individual partners will be compiled in the Exploitation and Dissemination Plan. A preliminary version of the Exploitation and Dissemination Plan will be generated mid-project. The general objectives of the dissemination activities are:

|

TUM | link |

| D5.6 | 24 month Progress Report | The project coordinator submits an annual progress report to the European Commission, when it does not coincide with the EC mandatory periodic reporting, indicating the status of the project. The structure of this progress report will be the same as that of the periodic report. | SZTAKI | link |

| D5.7 | Workshop / Final Exploitation and Dissemination Report | Organization of an International Workshop on Interdisciplinary Design Principles for Flexible Wing Aircraft Technology, to be held, and open to worldwide experts in the area, and EU graduate students. | TUM | link |

| D5.8 | Final Report | The project coordinator submits a final report to the European Commission, covering the whole lifspan of the project (while the 2nd periodic report which will be submitted at the same time will only cover the period M19-M36) The structure of this progress report will be the same as that of the periodic report. The report will be submitted after the closure of the project, aligned with H2020 regulation. | SZTAKI | link |